Single Cell Voltage Monitoring for Electrolyzers - HydraSafe

Making the efficiency, stability and safety of hydrogen electrolysis visible - with our new, modular system for monitoring every single cell in the stack

Diese Kunden haben die Feuchtemessung mit dem HUMY 301 automatisiert:

.png?width=50&height=62&name=Design%20ohne%20Titel(6).png)

The system measures the voltage of each individual cell within the electrolyzer, enabling the performance and condition of each cell to be monitored

Continuously records and stores the voltage data. This data can be used for analysis and diagnostics to optimize the performance of the electrolyser and make maintenance decisions

Integrates security functions, detects anomalies and sends warnings and alarms. This enables early detection of problems and security risks. Up to SIL 2

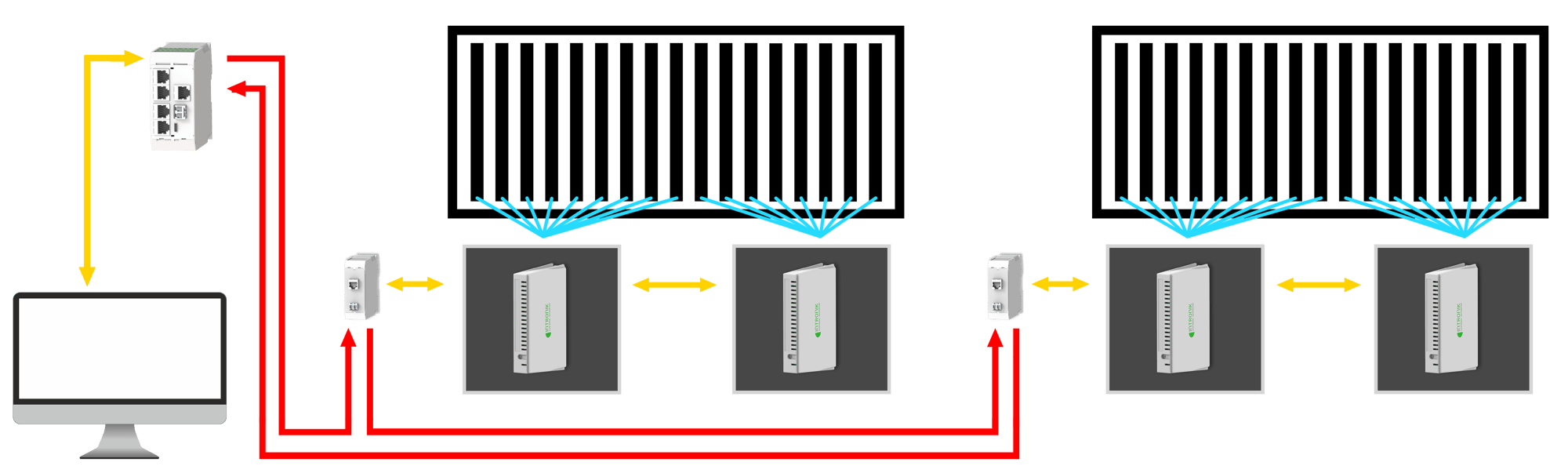

Transmits the collected data to a central evaluation unit, which analyses and visualizes the data. In addition to the MÜTEC analysis software, the data is available for further processing via standard protocols

Modular approach and standard components

The high degree of modularization enables a unique reduction in the complexity of the system and its installation. This ensures maximum performance, scalability and data quality in the most economical way.

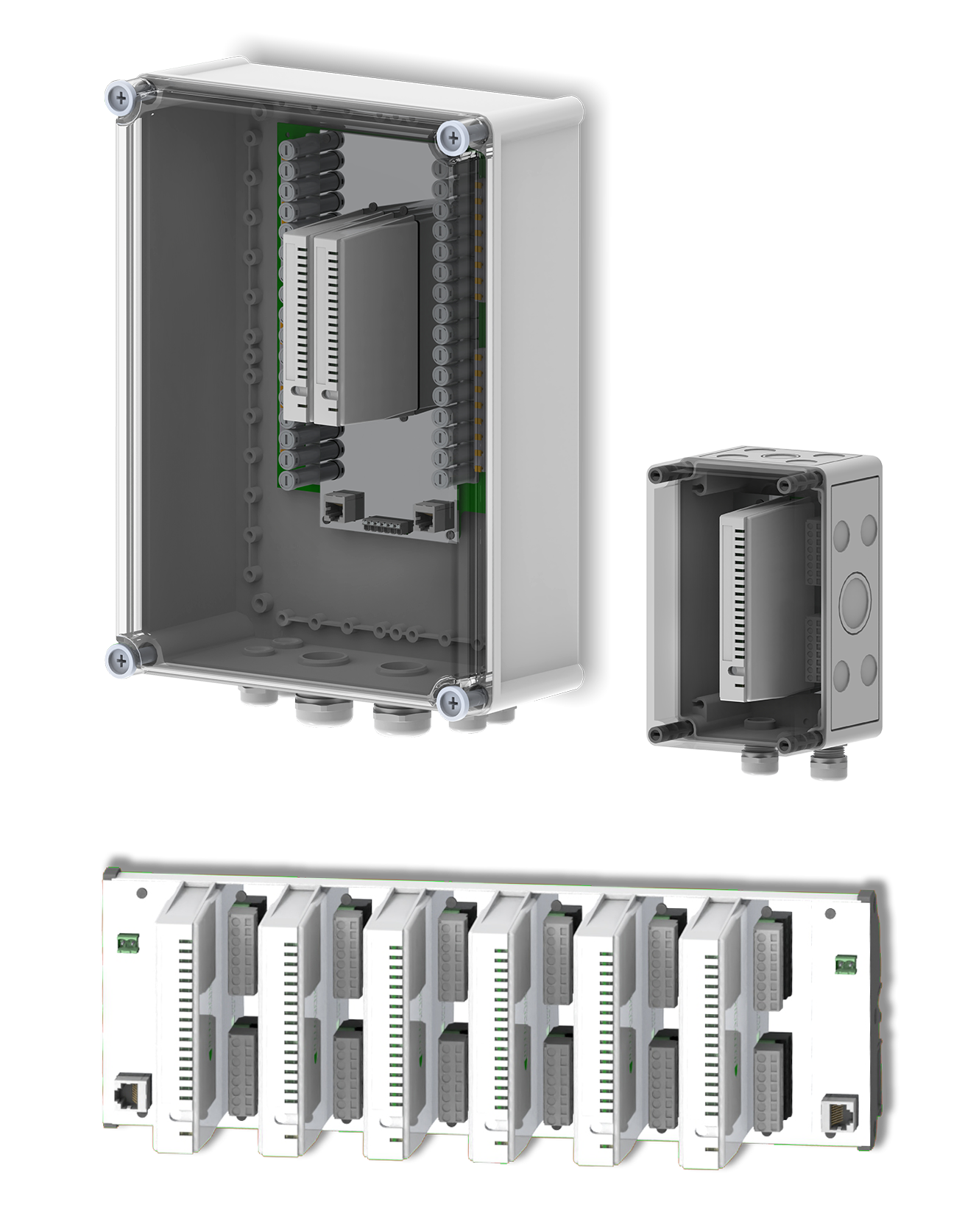

CORE

The CORE module offers precise voltage measurement for up to 16 cells and is easy to install thanks to its compact design. Various connection technologies are available for cell contacting.

Two versions of the CORE are available: a standard version and a SIL2-certified version. The COREs are standardized and calibration-free. Installation is made as easy as possible with an easy plug-and-play solution.

OBSERVER

The voltage values of all cells are collected in the OBSERVER. It is the brain of the HydraSafe system and the interface to an external PLC and to MÜTEC's analysis software. 512 cells can be monitored per device.

Two versions of the OBSERVER are available: a standard version and a SIL2-certified version.

The data is available via standard protocols, e.g. ProfiNet, ProfiSafe, OPC UA and Modbus TCP. If required, it can be adapted for other protocols. A Modbus TCP server and an OPCUA server are already included with the OBSERVER.

For your safety functions, the OBSERVER does not only give SIL2 rated absolute values of the cell voltages. It performs pre-calculations of proven-in-use parameters that can be used for the safety functions, without the need to program anything in the safety PLC.

GATE

The HydraSafe system is capable of measuring cell voltages at up to 10 readings per second. Multiplied by hundreds of cells, this results in a very large amount of data that has to be processed minute by minute. Very fast data transmission is therefore crucial for the performance of the system. HydraSafe uses Cat5E and higher category cables for this. Distances of up to 2 kilometers can be bridged with fast fiber optic cables. The signal is converted from Fast Ethernet to fiber optics in the GATE module.

Highly adaptable to all process types and sizes

Depending on the type, dimensions and topology of the electrolyzers, there are various installation options - including a plug & play system with pre-assembled wire harnesses

BASE

The BASE modules make it easy to assemble the COREs, connect them automatically in the correct sequence and can therefore significantly speed up the work involved in setting up the system.

They are available in three versions: as BASE-Rail, as BASE-Box for e.g. 16 or 32 cells.

If required, the BASEs can be supplied with integrated fuses or pre-assembled cable harnesses, further reducing the installation work on site.

All BASE modules can be combined into systems of any length in just a few simple steps.

A big focus of the development was speeding up the assembly of the electrolyser. Pre-assembly in our factory enables quick assembly on site. Care has also been taken to ensure that there is sufficient space for connecting the cables and that the same short cable harnesses are always used. The HydraSafe system can be easily expanded by connecting several BASEs together. This makes it suitable for all electrolyser sizes or scale-up.

Increase the safety and transparency of your hydrogen production now

Improved operation of the electrolyzer with HydraSafe

HydraSafe makes it possible to detect faults, membrane degradation and critical events in the electrolysis process in good time and to operate the electrolyser efficiently and safely:

- The system defines a range of acceptable voltage for each cell - this is possible at any time and in all operating states (commissioning, normal operation, etc.).

- If the voltage of an individual cell falls below or exceeds a threshold value, an alarm is triggered or the electrolyzer is shut down.

- The cell voltage monitoring system uses the cell voltage to detect numerous events that can occur on an electrolyser, e.g. holes in the membrane, leaking cells, insufficient electrolyte supply, damage to the anode or cathode coating, failure of the electrolyte concentration control, short circuits, etc.

- HydraSafe protects the electrolyser against consequential damage caused by malfunctions, e.g. insufficient electrolyte supply, defective temperature control

- The system provides valuable information for performance analyses and enables the electrolyzer to be optimally adjusted at all times

- With HydraSafe it is possible to implement a predictive maintenance strategy, e.g. it provides valuable findings for preventive membrane replacement