Inline-Moisture Measurement for Bulk Materials - HUMY 301

Monitor the moisture of your product permanently in real time, without manual measurements. Save working time, travel, material and laboratory costs.

These customers have automated moisture measurement with the HUMY 301:

Diese Kunden haben die Feuchtemessung mit dem HUMY 301 automatisiert:

Moisture in solids has a strong influence on the quality of a product and the economic efficiency of production. This is why moisture must be measured regularly during the production process.

Manual Moisture Measurement

A single measurement can even take up to half a working day.

Create schedules and work plans for the measurementsPrepare containers for sampling

Walk or drive to the measuring point

Take several samples per measurement

Analyze and evaluate samples in the laboratory

Automatic moisture measurement with the HUMY 301

Open the software program and read off the measured value - it only takes a few seconds.

How the HUMY 301 works

The new HUMY 301 determines the product moisture of the bulk material in real time directly in the product flow, e.g. in the screw conveyor, on the conveyor belt or in the hopper outlet of a silo. The results can be clearly displayed on a PC or to a DCS. This allows you to continuously monitor the production process. The measurement results can also be used to control a dryer or automatic humidification. Manual measurements are then completely superfluous. Unlike other sensors, the HUMY is designed for a broad moisture spectrum, from 0.1 % to 85 % moisture content. The HUMY 301 uses a capacitive measuring method that determines the entire water content of a material - and not just its surface. To do this, the sensor's field lines penetrate up to 200 mm deep into the material. The measurement result has an accuracy of up to 0.1 % - depending on the bulk material and measurement situation.Typical areas of application for our moisture analyzer (PDF)

Typical applications for the HUMY 301 include the drying of grain, starch, gluten, fish meal, cheese, sugar production, fertilizer, wood pellets, textile fibres, sand, cement, coal, iron ore, sinter and the extrusion of plastic pellets.

Convenient calibration

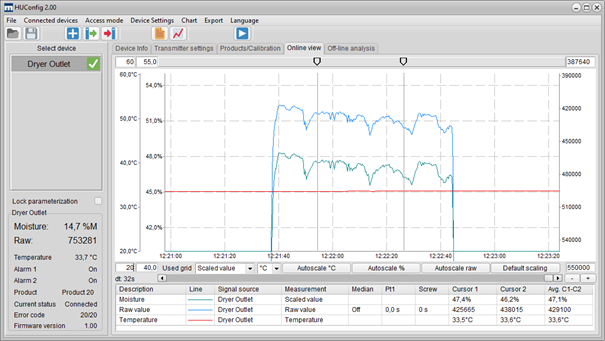

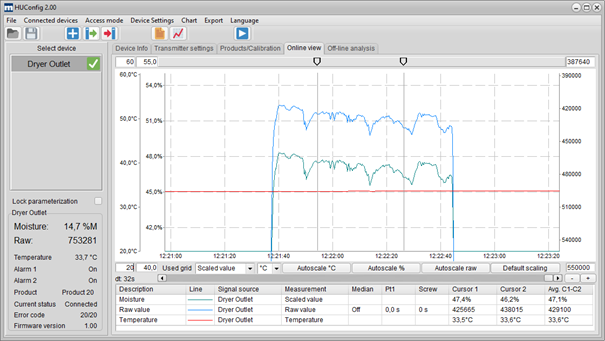

The new HUMYConfig software provides the user with modern Windows software with which the humidity sensor is calibrated to the respective product. The main features are:

- A graphical user interface for analyzing the measured values

- Up to 8 Sensors can be displayed together

- Intuitive user guidance

- Convenient calibration directly in the graphic

- Additional plausibility check

- Improved filter settings, e.g. for screw conveyors

- Full access to all sensor settings,

e.g. for configuring the new digital inputs - Long-term storage on industrial PC possible

- Offline calibration possible

The most robust moisture sensor in its class

The HUMY 301 is the most robust inline humidity sensor on the market. The entire electronics are encapsulated so that the device can be used under demanding environmental conditions. Sensor surfaces made of POM, ceramic or Teflon allow it to be used with a wide variety of materials. And the stability of the sensor design ensures that even continuous use on a vibrating chute is possible without any problems.

Reliable measurement results and fast material changes

For its class, the HUMY 301 offers one of the best measurement results on the market. Even at low moisture levels, e.g. 0.5%, the sensor shows low drift and delivers constant, reliable results. The HUMY must be calibrated to the material and the material density, load and conveying speed must be sufficiently constant. The HUMY 301 also makes it easier to switch from one product to the next. Up to 24 products can be calibrated and saved, and up to 16 can be selected via four digital inputs with extended functionality - simply integrated into the PLC or with an additional selector switch.